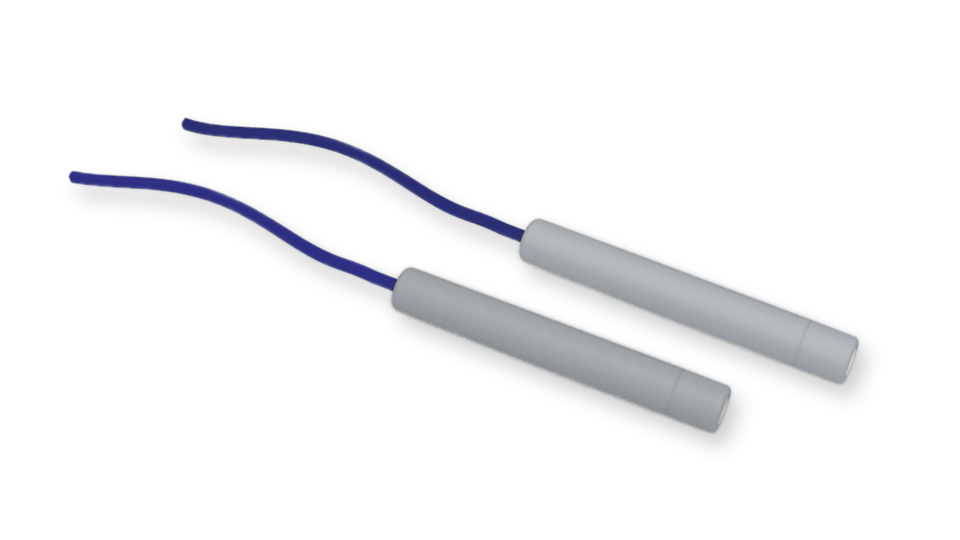

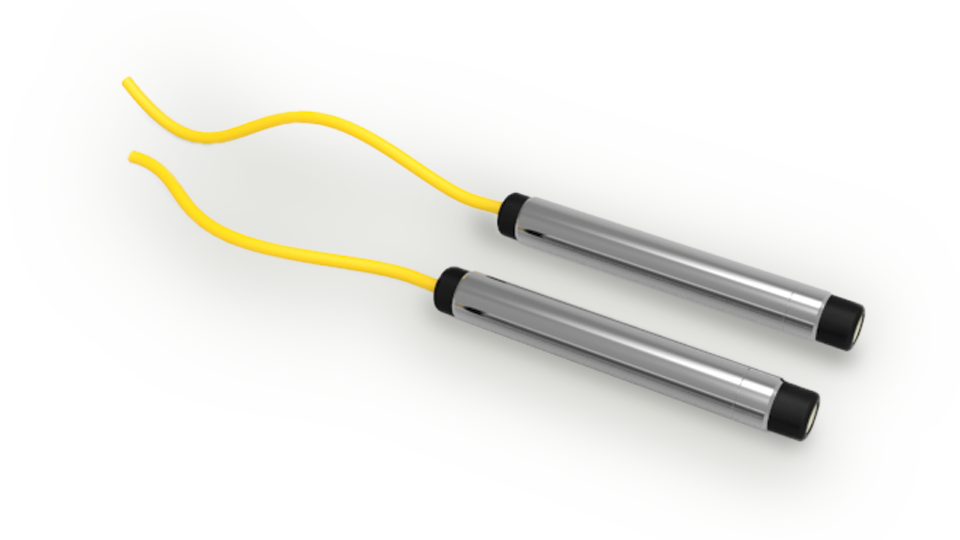

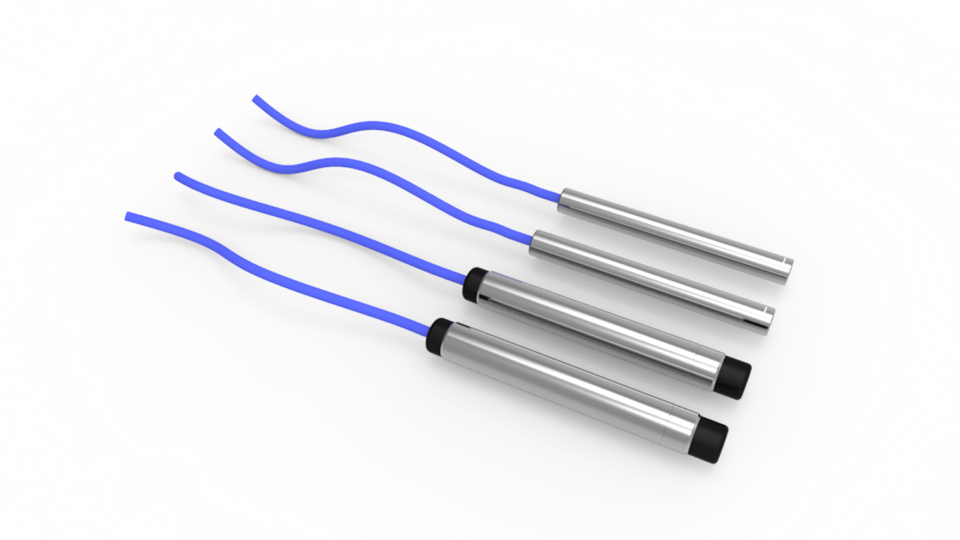

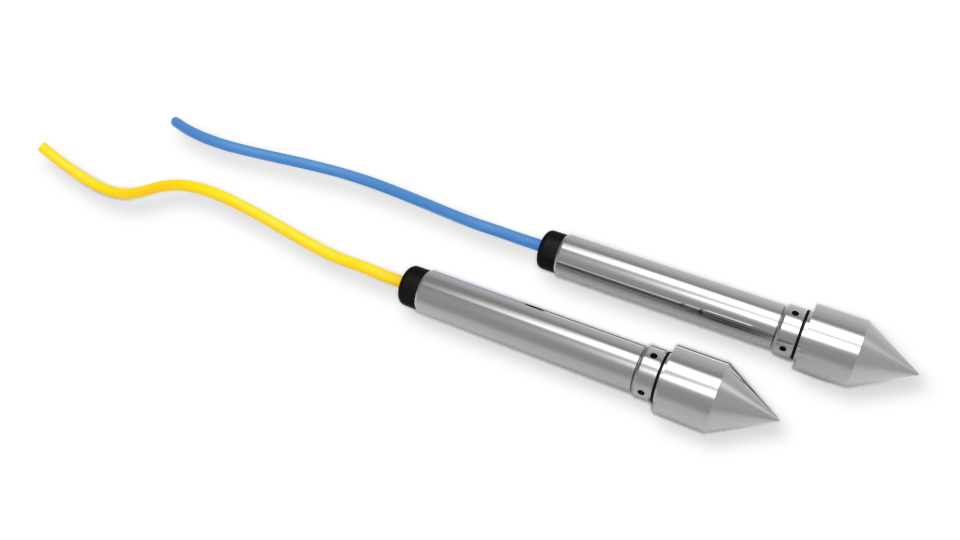

Drive-in piezometers

Reference products codes: PK45I, P235I

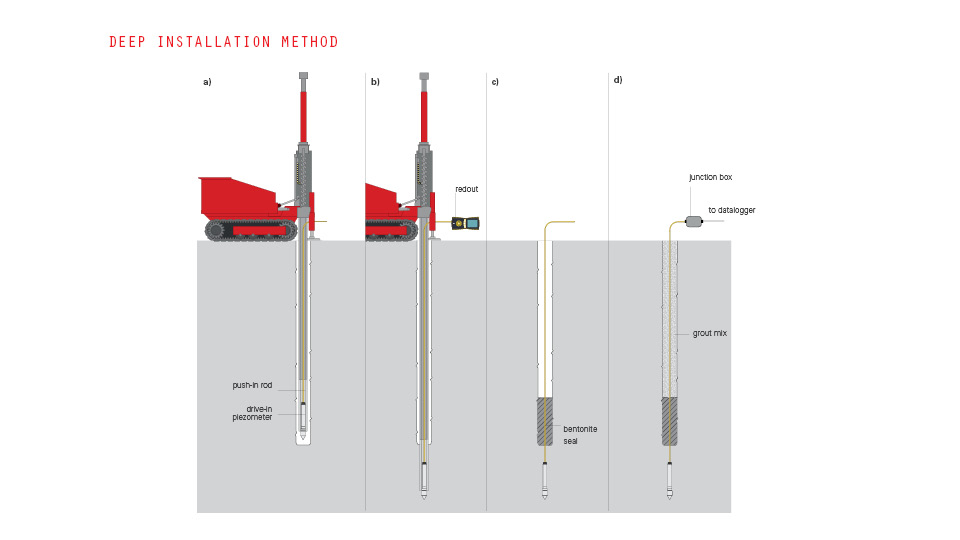

Drive-in piezometers, also called push-in piezometers, are designed for installation in soft clays, organic or fine grained cohesionless soils.

The piezometers are pushed directly into the soil using conventional cone penetrometer or drilling rods with adapters. The large diameter nose cone decreases the chance of overpressure while the piezometer is pushed into the soil.

APPLICATIONS

• Pore pressure in soft soils

• Dams and fill embankments

• Dewatering activities

• Natural or cut slope sites

• Deep excavations

• Diaphragm walls

FEATURES

• Cable length does not affect reading

• Long working life and reliability

• Built-in surge protection (vibrating wire only)

• Built-in temperature sensor

• Dynamic pore pressure monitoring (piezo-resistive only)

Resistive pressure transducer sensor is a spin off from thick film technology using the piezo-resistive characteristic of specific resistive inks. Resistors, formed using screen printing techniques, are deposited on a deformable ceramic diaphragm substrate to form strain gauge arrays. Strain changes from external loads applied to the deformable ceramic diaphragm result in resistance changes of the strain gauge arrays.

The electric signal from the strain gauge arrays is directly proportional to the stress applied to the diaphragm. Sensor is constructed of a ceramic, analogous to a crystal structure, to form a pressure diaphragm chemically inert with near perfect mechanical characteristics. Screen printed resistors are deposited onto the diaphragm to form a 4 arms Wheatstone bridge.

A fixed excitation voltage is applied to one diagonal of the circuit. Strains experienced by the diaphragm will change the values of the individual resistors within the Wheatstone bridge resulting in a bridge unbalance. This unbalance produce an output signal from the other diagonal of the Wheatstone bridge, directly proportional to the applied stress.

An electronic board converts this signal into 4-20 mA suitable for transmission over long distances to remote readouts or to data acquisition systems.

Vibrating wire transducer is essentially composed by a taut wire clamped at its ends and tensioned so that it is free to vibrate at its natural frequency. The frequency of vibration varies with the wire tension and thus small relative movements between the two end clamps.

With VW transducers frequencies rather than voltage levels are measured, so a dedicated readout/datalogger must be used to measure the resonant frequency. These ones excites the VW transducer, measures the response, performs some calculations on the response, and returns the result.

SISGEO VW transducer uses ‘pluck and read’ method and not ‘auto resonant’ method; when the readout/datalogger plucks the wire a magnetic attraction is created to the coil and the wire start to vibrate and it causes an alternating voltage of the same frequency of the natural frequency of the wire; the voltage signal is transmitted on the cable and read from the readout/datalogger.

VW transducers have a reputation for long expected life and long-term stability.

Readable by

Questions

about this

product?

about this

product?

Datasheet

Manual

Faq

Questions

about this

product?

about this

product?

Datasheet

Manual

Faq